Lambda Sensor Bosch Wideband LSU 4.9 Oxygen Sensor (O2)

This is a Genuine Bosch sensor, part number 0 281 004 821

Details:

- Thread: M18 x 1.5mm

- Cable Length 62.5cm

- Tightening Torque: 40Nm

- Measurement Range: Lambda 0.65 to infinite

- Fuel: Gasoline(unleaded)/Diesel/E85

- Sensor: Dual cell zirconium dioxide current limiting sensor with integrated heater.

Note:

- The sensor connector has an individual calibration resistor. This resistor is critical for the correct operation of the sensor and must not be removed, or the connector changed.

- Connector has a different pinout to the LSU 4.2

See our mating 6 pin LSU 4.9 connector here

ECU Calibration Settings

It is vital that your ECU can support the LSU 4.9 Lambda sensor and that the O2 Sensor type configured to "Bosch LSU 4.9". Damage will occur otherwise.

Why is the LSU 4.9 better than LSU 4.2:

- Faster light off time, approximately 10 seconds from engine start (compared with 20 seconds)

- Larger Measurement Range (from Lambda 0.65 compared with Lambda 0.7)

- Improved design with better contamination resistance and less signal drift over the service life of the sensor.

- Greater service life (250,000km compared with 150,000km)

- Compatible with diesel engines

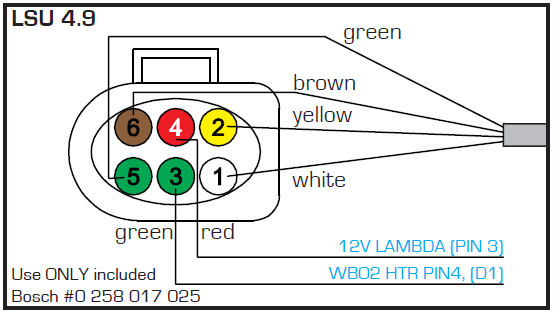

Pinout Diagram (looking from the vehicle wiring loom side):

Pinout Reference:

1. IP

2.VREF

3. H-

4. +12V (H+)

5. RCAL

6. VS

Installation and Mounting:

- The sensor should not to be fitted near to the exhaust pipe outlet, otherwise exhaust gas may be contaminated with outside air due to pulsing effects resulting in a reading closer to Lambda 1.0 than expected.

- The exhaust-gas passage upstream or near to the sensor must be free of leaks in order to avoid the effects of atmospheric contamination.

- Locate the sensor as close to the engine as practical noting the maximum operating temperature (1,030°C peak, 930°C continuous).

- Installation angle should be inclined at least 10 degrees from the horizontal (cable end upwards). This prevents the pooling of liquids between sensor housing and sensor element during cold start. Do not mount vertically, as this promotes heat soak into the sensor.

- Use a very small amount of high temperature anti-seize on the thread.

- Sensor threads must be covered completely by the bung (11mm of thread).

- The sensor is fragile and must be handled with care.