Intercooler Pipe Size Calculator

Posted by Hotside - Dave on 26th Jan 2024

Is 3 inch hot side piping too big?

Intercooler pipe size can definitely be too small. For a given airflow rate, a smaller pipe requires a high flow velocity which creates more drag, or more pressure drop.

Too small = undesirable pressure drop.

Too large = additional time taken to fill your charge pipes (and intercooler).

Obviously the intercooler pipes need to be big enough without causing an unreasonable pressure drop but without causing reduced throttle response.

The downside trade-off with too large of intercooler charge air piping is a longer transient boost response since you're increasing the volume of ducting that you need to pressurise. The effect however is quite small (less than 0.1 second increase in effective spool time comparing 2”and 3” tube diameter over several feet of tube).

Intercooler duct diameter should be sized to have an air velocity of approximately 200 – 300 ft/sec (according to the Garrett Motion Knowledge Centre). Corky Bell, in chapter 5 Intercooling, of his legendary book Maximum Boost explains that the maximum air speed we want through pipes is around 450 ft/sec or 0.4 Mach, anything above this number and flow loss increases rapidly.

The speed of sound is higher after the compressor outlet due the higher temperature, so Mach 0.4 is probably around 10% higher in your hot side pre-intercooler pipework compared with the speed of sound in air at ambient temperature.

Bends and Transitions

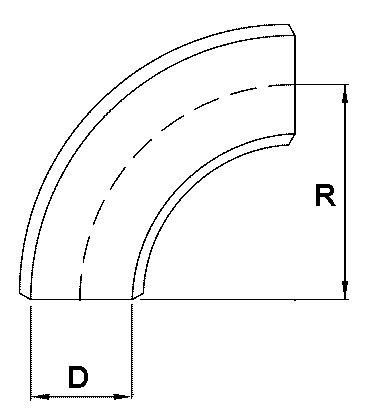

Assume for every 90 degrees of bend angle we lose 1% of flow efficiency. eg 2 bends of 45 degrees equals 90 degrees.

For bends in the tubing, a good design choice is a bend radius 1.5 times the tubing diameter or larger, anything with a tighter radius than 1.5D will incur undue pressure loss. The flow area must be free of restrictive elements such as sharp transitions in size or shape.

So minimise the number of bends, avoid sharp bends and use large radius bends whenever possible.

Also avoid rapid area changes. If a change in diameter is required then use a gentle taper. The included angle of the cone should not exceed 15° (7.5° each side).

Charge Air Density

Pressurised air is more dense than ambient air. For example two cubic feet of air before the compressor can be squashed into a one cubic foot box, so the actual air flow velocity in the hot side pipework is less than just using the raw pre compressor air flow rate for the calculation.

Unfortunately it's not quite that simple because the gas laws and compressor efficiency both mean that the charge air temperature after the compressor is warmer, significantly warmer in some cases.

The calculator below takes all this into account and provides a guideline as to whether your 3 inch hot side piping is too big?

Inputs:

Results:

All blogs are copyrighted. No re-posting, plagiarising or other forms of flattery is permitted.