The Case for Lambda

Posted by Hotside - Dave on 28th Jul 2025

The Case for Lambda (in Modern Tuning)

Why Tune in Lambda instead of AFR?

Introduction

Some tuners still understand internal combustion engine fuel mixture in terms of Air Fuel Ratio, and prefer to communicate in that language, rather than Lambda.

Lambda (λ) is the eleventh letter of the Greek alphabet and is used to represent many engineering and scientific terms. Lambda is unitless, and a Lambda of value "one" denotes unity or nominal. In the context of engine tuning Lambda one represents a stoichiometric air fuel ratio. i.e. A chemically correct charge mixture with theoretically, no remaining oxygen and no unburnt fuel. Lambda < 1 = rich and Lambda > 1 = lean.

Here we will argue why it makes more sense to talk and think Lambda values rather than AFR. But first, a brief history of air fuel ratio measurement.

History of AFR Measurment

by Weight

Air to fuel ratio was historically literally measured by weight, pounds of air divided by pounds of fuel. Intake charge air flow was measured in pounds of air, and fuel usage was also measured by the pound. The number of pounds of air in a given time frame was divided by the number of pounds of fuel used to give an "air fuel ratio".

The problem with quantifying the charge mixture ratio by weight is that different fuels (and seasonal variations in the composition of the same fuel) have different weights and therefore different air-to-fuel ratios. When speaking about air to fuel ratio the actual type of fuel also needs to be stated for context.

Carbon Monoxide Percentage

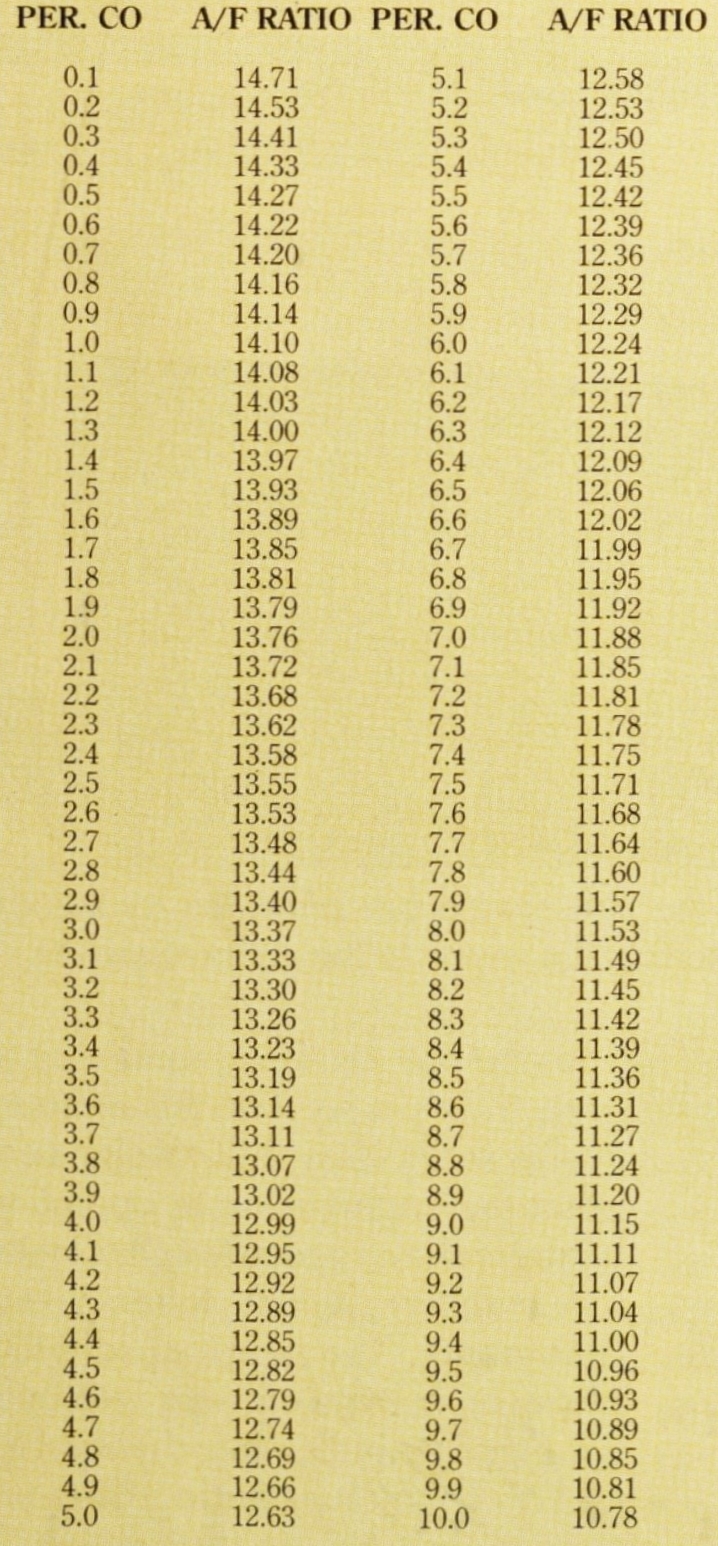

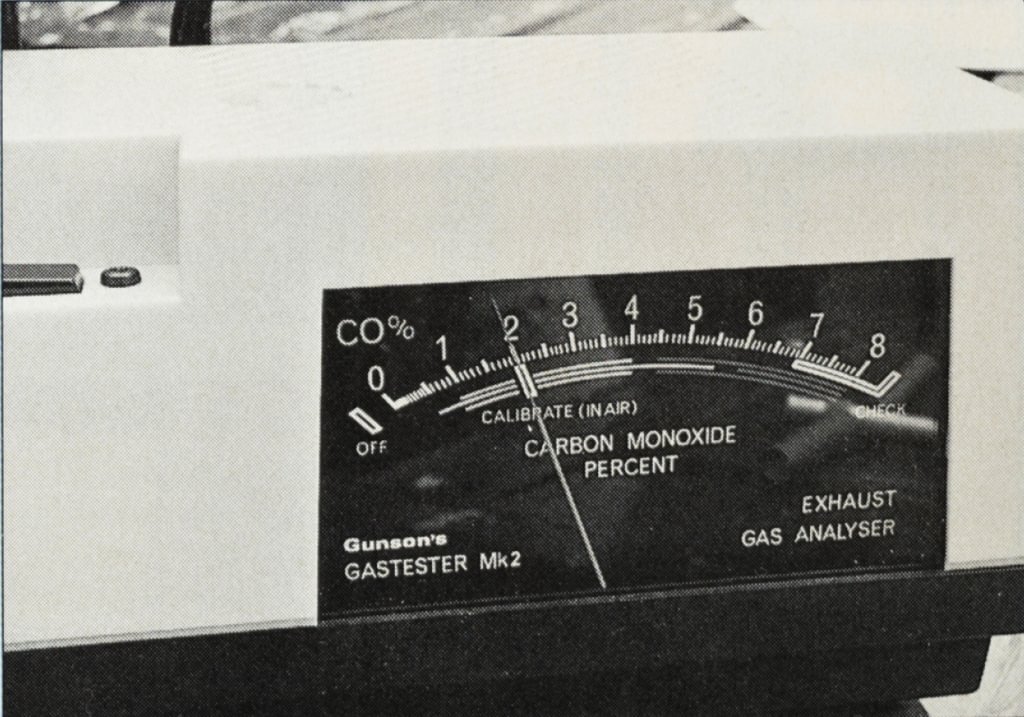

Carbon Monoxide percentage meters were a common tuning tool before modern wideband O2 sensors. CO% in the exhaust gas correlates directly with air fuel ratio and was a very useful tuning tool. The "language" of AFR was "percentage CO", i.e. a higher CO% meant a richer AFR. You would aim to tune for somewhere around 5% CO or higher at wide open throttle.

CO% vs Gasoline AFR table and CO% meter from the 1993 issue of Hot Rod magazine:

Oxygen Sensor (Lambda Sensor)

1800's

Arguably, the Lambda Sensor history can be traced back to 1887 when Nobel prize winner Walther Hermann Nernst developed the “Nernst Equation”. The Lambda Oxygen Sensor is sometimes referred to as a Nernst Cell.

1960's

The original zirconia ceramic oxygen sensing element was developed by the Robert Bosch company under the supervision of Günter Bauman.

1970’s

Oxygen sensors saw increased development due to EPA clean air regulations and first automotive production use with Volvo in 1976.

1980's

Development pressure continued with regulations like USA's IM-240. Heated sensors were invented.

1990's

NTK introduced a variation on the narrowband zirconia sensor that could measure a wide range of air fuel ratios. Dubbed the "wideband" sensor.

2000's and Beyond

Costs continue to fall and development continues.

| Lambda Sensor | Parameters |

| 1st and 2nd generation | No heating elements, open loop control whilst cold ~2 mins |

| 3rd generation | Heating elements, response time < 1 min |

| 4th generation | Heating elements, response time < 15 s, fast heating |

| 5th generation | Linear output, response time < 10 s, rapid reaction, good accuracy |

AFR and Lambda

The Basics

Air-Fuel Ratio (AFR) is the ratio between air and fuel by mass.

Lambda describes the ratio between the actual AFR and the stoichiometric AFR. Lambda is dimensionless and is independent of the type of fuel being used, making it the normalized version of AFR (fuel agnostic). Lambda 1.00 equals stoichiometric for any fuel type. Values below 1.00 mean a rich mixture (more fuel), above 1.00 implies lean (less fuel).

For gasoline, the stoichiometric AFR is 14.7:1, meaning 14.7 parts air to 1 part fuel (by weight). However, the stoichiometric AFR value changes with fuel type:

| Fuel | Stoich Lambda |

Stoich AFR |

"Rich" Lambda |

"Rich" AFR |

| Gasoline* | 1 | 14.7:1 | 0.85 | 12.5:1 |

| E10 | 1 | 14.1:1 | 0.85 | 12.0:1 |

| VP MS109 | 1 | 13.4:1 | 0.85 | 11.4:1 |

| E85 | 1 | 9.8:1 | 0.85 | 8.33:1 |

| Ethanol | 1 | 9.0:1 | 0.85 | 7.65:1 |

| Methanol | 1 | 6.47:1 | 0.85 | 5.50:1 |

| Nitromethane | 1 | 1.7:1 | 0.85 | 1.45:1** |

*Oxygenators such as MTBE or alcohols lower the stoichiometric ratio (can be as low as 14.1:1).

**Don't try this at home.

As can be seen in the table above when switching fuels, Lambda stays the same making Lambda a very simple way to state AFR. For example a Lambda reading of 0.85 = fuel rich mixture, regardless of fuel type.

Conversion

To convert between AFR and Lambda, simply use the following formulas:

Lambda = AFR / Stoich AFR

AFR = Lambda x Stoich AFR

AFR Popularity

AFR has long been favored by some for its simplicity, especially when tuning gasoline engines. Wideband O2 Sensors often display gasoline AFR by default, and many tuning communities have developed AFR-based tuning heuristics (or mental shortcuts).

However, this approach has critical limitations:

- Tied to specific fuels. e.g. your software may not have the option to change to a specific fuel type e.g. MS109

- Prone to conversion errors. I have seen tuners tie themselves in knots trying to convert between different fuels.

- Misleading interpretations when different fuels are used or fuels are blended (e.g., ethanol blends).

- Some tuners continue to use a gasoline AFR scale even when using ethanol blends, which can be confusing and misleading.

Why Lambda?

The modern oxygen sensor determines how much excess oxygen or excess fuel is in the exhaust stream. Fundamentally, it doesn't know what fuel type is being used and simply reports the ratio of fuel to oxygen. The higher layers of software might convert to AFR, however, it's measuring Lambda.

Lambda sensors are Fuel-Agnostic meaning your sensor simply doesn’t care what fuel you’re using. Whether it’s E85, methanol, or race gas, Lambda 1.0 always means stoichiometric.

There are many reasons to tune with Lambda:

- Reduced cognitive load. It's mentally easier to instantly understand mixture status (e.g., Lambda 1 = stoich, Lambda 0.80 = 20% richer than stoich)

- Makes tuning easier, especially with flex fuels

- Many modern aftermarket ECUs operate in Lambda. AFR values are not an option.

- CAN-based wideband controllers usually broadcast in lambda

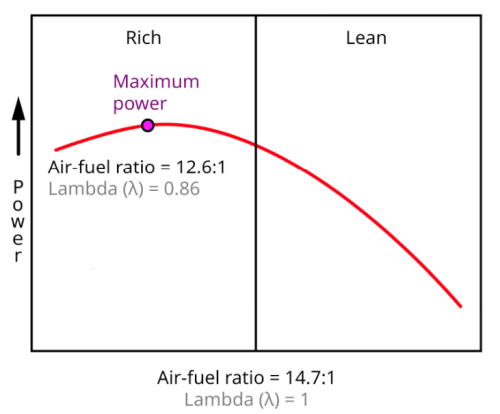

- Removes the uncertainty. Using Lambda removes the guesswork from tuning. A Lambda value of 0.85 might be an optimal target for power, regardless of whether you’re burning E10, E85, or even pure ethanol.

Why Rich = More Power?

It's well known that maximum power requires a slightly richer than stoichiometric mixture, but why?

1. Air is the limiting factor. By having a slightly rich mixture, every molecule of oxygen is used. Ettore Bugatti stated: “Engines do not drink, they breathe”.

2. The additional fuel from a richer mixture further cools the inlet charge temperature via the latent heat of evaporation. A cooler inlet charge is a denser inlet charge, meaning more air per engine cycle.

3. The cooler, fuel laden inlet charge also cools the combustion chamber warding off detonation and allowing higher boost and/or compression ratio/ignition timing.

4. Not often mentioned or understood is that a rich mixture (or oxygen deficient mixture) produces some CO products rather than CO2 products from combustion. The CO reaction releases more net energy for each available O2 molecule.

Conclusion

Tuning using AFR to interpret and communicate air-fuel mixture is workable, but it’s inconsistent, fuel-dependent and potentially misleading. Thinking in terms of Lambda offers universal consistency, mental clarity and simplifies tuning logic.

Whether you're a beginner or a pro, switch your tuning mindset to Lambda and educate your customers.

"Think Lambda and forget AFR"